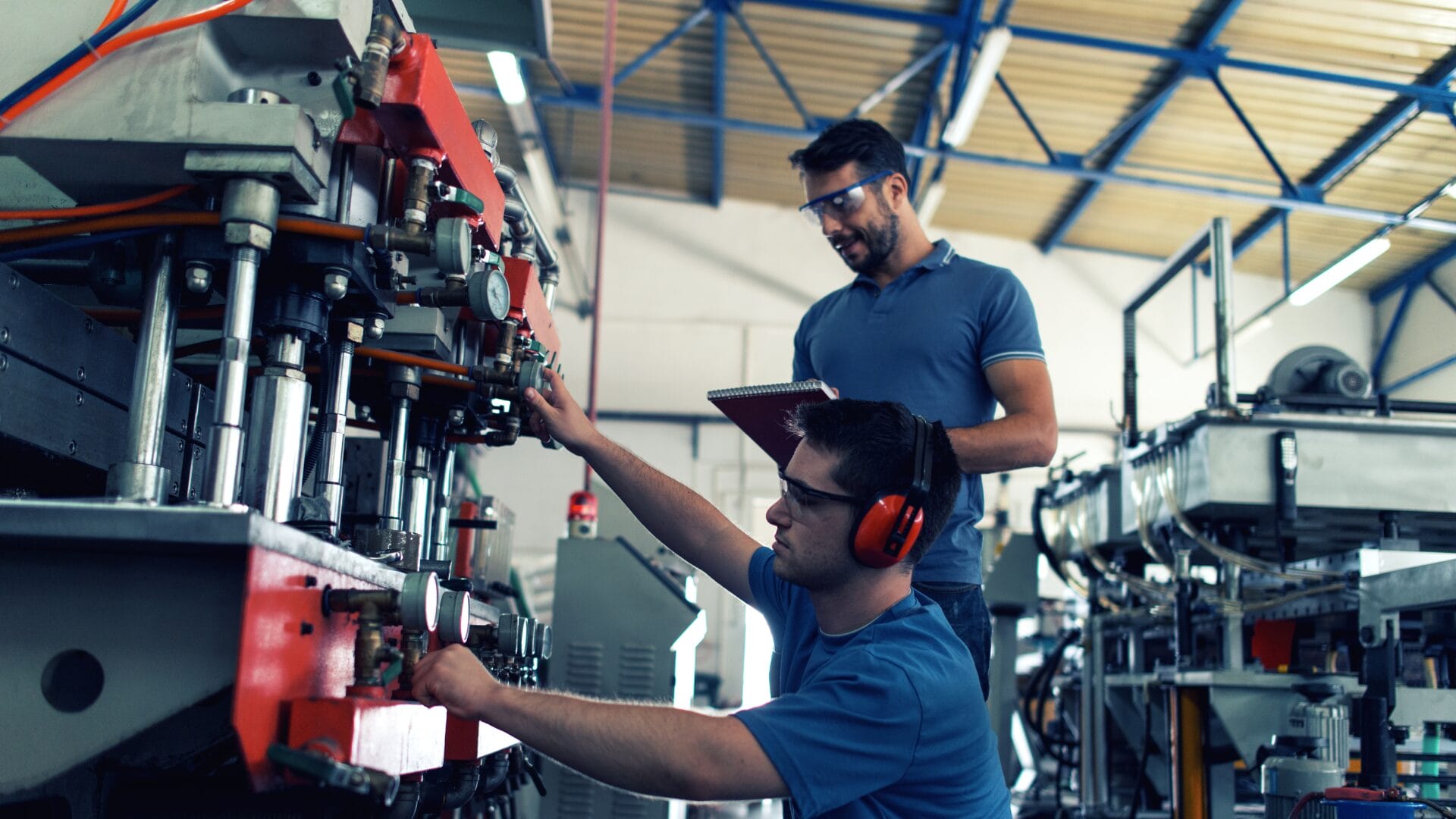

The manufacturing sector is experiencing a fast-accelerating shift towards automation. Against a general backdrop of rapid tech development, manufacturing has proven particularly well placed to benefit from emerging technology.

Today’s factories are hugely changed from the state-of-the-art of only 10 years ago. Breakthroughs such as additive manufacturing, improved automation, and greater machine intelligence are the driving forces, as manufacturers truly move to Industry 4.0.

While the Fourth Industrial Revolution may sound like a grandiose term, today’s smart factories are a giant stride beyond what has gone before. They benefit from a convergence of technologies that, together, enable improved operational efficiency, better integration with the supply chain, and new directions in manufacturing.

At their heart, the flow of data defines and enables a new paradigm. Smart sensors and cloud computing enable rich data-gathering from the factory floor and beyond. Improved automation increases output, and tighter integration with suppliers helps achieve new levels of lean operation.

Tying it all together, breakthroughs in machine learning provide unprecedented insight into the way the factory operates, and a responsiveness that simply wasn’t possible before. Smart factories are more efficient, operate with reduced downtime, and can reach new heights in quality control.

However, the integration of AI also poses significant risks to manufacturers. Wider reliance on data and the cloud creates new attack surfaces, increasing the risk of – and vulnerability to – cyber crime. Automation can be a challenge to workforces, who need to be upskilled, and who may be concerned they’re being replaced. And over-reliance on automation can lead to mistakes and a lack of accountability.

For global manufacturers, a critical – but often overlooked – enabler of success in AI adoption is the ability to adapt content, processes, and governance to different languages, markets, and cultures. Success in training and using new AI systems depends on accurate reference materials, and governance that’s appropriate to the diverse markets and workforces underlying the business.

With the groundwork laid, let’s explore how AI is reshaping core areas of factory operations — from the supply chain to predictive maintenance and quality control.

Assembling intelligence: the role of AI in smart factories

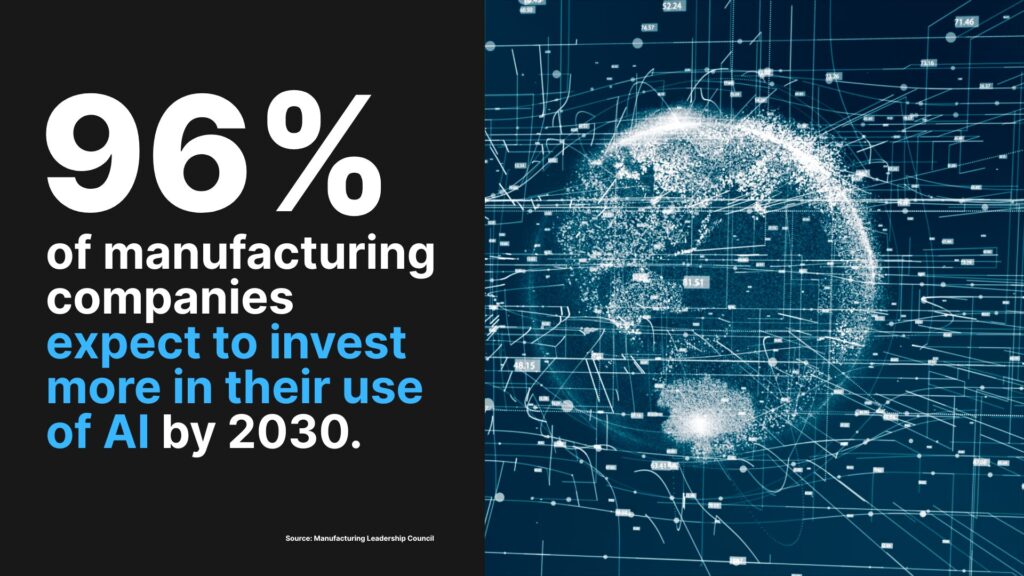

Despite the immense promise, manufacturers are being methodical in their uptake of AI. In a 2023 survey, the Manufacturing Leadership Council found that 96% of companies expected to invest more in their use of AI by 2030.

However, only 28% already had AI projects in place, and most manufacturers were still either researching or developing awareness within the business. Yet the benefits of AI are already clear, and they start in the supply chain.

Supply chain optimization

Internet of Things (IoT)-enabled components and shipping materials mean that there is now greater, more granular data available from suppliers, warehousing, and factories themselves.

AI algorithms can analyze global demand and logistics patterns to better understand how the supply chain functions, and how it can be optimized. AI insight and decisioning can help revitalize procurement strategies and inventory levels, saving money and improving production efficiency.

Some manufacturers are already pushing these ideas further, integrating AI and IoT to create self-monitoring systems that optimize production in real time.

Sensors, data logging and AI can further streamline production in new ways that wouldn’t have been possible just a few years ago.

At BMW’s iFACTORY, new ‘Car2X’ technology allows vehicles in production to monitor their own build progress, and even guide plant workers to the correct parking space once the car is complete. In the innovative, AI-driven system, cars also use their forward-facing cameras to monitor the vehicle ahead, identifying and alerting to quality control errors, such as a missing warning triangle.

This ability to catch issues during production is just one way AI is transforming quality assurance on the factory floor.

Automated quality control

This is a strong example of another powerful benefit of AI in manufacturing: automated quality control. In the smart factory, vision-based systems recognize and track key parts and assembly processes, for example identifying when stages or components are missed. With defects spotted in real time, it’s quicker and less costly to rectify mistakes, resulting in greater efficiency and less waste.

In this way, AI plays a critical role in elevating build quality. Similar video and audio systems can be used to analyse finished products, for example comparing the sound of a completed vehicle against a reference library to identify noises that might signal a failure. There’s greater consistency, and the result is a better end product.

But ensuring product quality is only part of the equation. AI also helps factories stay up and running through smarter maintenance strategies.

Predictive analytics

But AI needn’t just be applied to the supply chain and products. With smart data gathering embedded in robotic factory equipment, AI-driven monitoring systems can analyse performance data to predict equipment failures before they occur.

Preventative maintenance can be scheduled, preventing disruption, and minimizing repair costs. The German technology group Siemens says that using AI in this way can increase overall plant availability by as much as 30% – a huge productivity benefit.

Beyond daily operations, manufacturers are now using AI to plan for the future, designing facilities and processes that can scale and adapt globally

AI also can also be a key tool in factory planning and design. The use of digital twins – where a real facility is modelled in software – allows planners to test and optimize not only the physical location and layout of a facility, but also how its supply chain and other dependencies can be optimized for the greatest return. This successful plant can then be replicated globally.

Foxconn, the major technology group, announced a collaboration with NVIDIA to model and scale its factories and supply chains via digital twins. The business explained that AI modelling enables it to unify standards in strategic global markets. It also noted that the ability to rapidly re-model in the case of supply chain disruption or a changing market would help ensure production continuity.

Digital twins also allow businesses to rapidly benchmark changes in environmental factors, such as a factory’s power source. By modelling shifts in power or operating times, factories can be optimized to minimize power use, and make the most of cheap or renewable energy when available.

Despite these exciting advancements, manufacturers are right to approach AI with caution, particularly when it comes to the people, systems, and safeguards that surround the technology

Bürkert Fluid Control Systems is a leading manufacturer of measurement and control systems for liquids and gasses with subsidiaries in 35 countries. Bürkert

Discover how Bürkert used Phrase to save 20% in costs while boosting productivity

The risks: workforce displacement, cyber threats, and over-reliance on AI

The advantages of smart factories are many, but manufacturers are exhibiting caution for a reason. Aside from the investment, planning and other factors required to build or modernize plants, AI comes with risks that need to be understood and mitigated.

Workforce displacement

AI and automation are reshaping the manufacturing workforce. Replacing repetitive and unrewarding tasks reduces the need for less skillful labor, but in turn it creates a demand for highly-skilled workers to manage and maintain smart systems. Manufacturers must upskill their staff, but global labor markets vary, and it can be challenging to reskill workers fast enough to keep pace with technological progress.

Additionally, not everyone welcomes automation. A survey by human resources software company ADP found transportation and warehouse workers were particularly cautious about workplace AI, and that only 8% of workers with a repetitive job believed it would have a positive impact on them. If not managed well, introducing AI and automation can lead to resistance, particularly if employees feel they’re being replaced.

ADP’s survey also found a sharp difference in global attitudes to workplace AI. Twenty seven percent of workers in the Middle East and Africa believed the technology would positively impact their job, but just 19% in Latin America, 16% in Asia-Pacific, 13% in North America, and 11% in Europe. Clearly, a one-size-fits-all approach to a global AI rollout could encounter cultural differences, and create a digital divide between regions.

Cybersecurity

Humans aren’t the only risk factor to AI adoption. Smart factories rely on myriad data points collected throughout the supply chain, in the factory, and downstream to the consumer. These exist in supplier systems, are moved between data platforms, and may be processed in cloud or hybrid infrastructure. Each system provides would-be cyber criminals with an attack surface, and potentially a way into the business’ most valuable secrets.

More than that, the interconnectedness of firms within the supply chain means that an attack on one can impact many others.

For an example, look no further than the 2023 attack on Clorox, the US cleaning products manufacturer, which took out systems including those used by customers to place orders. As a result, the company said it expected net sales to fall 23-28% compared to the previous year.

Interestingly, Clorox also said that “the impact from the cybersecurity attack more than offset the benefits of pricing, cost savings and supply chain optimization”.

As with any cyber breach, these financial losses go hand-in-hand with huge reputational risks, not to mention the potential regulatory fallout.

Over-reliance on automation

Manufacturers embracing AI at scale face another, more subtle risk. While AI can accelerate and improve accuracy in decision making, over-reliance on automated systems can have unintended results.

Today’s machine-learning AI models can only recognize patterns and make decisions based on the data with which they’ve been trained – they lack a human’s understanding of the wider context in which they’re operating. As such, they may react inappropriately to an unpredictable event, or fail to react at all.

There are already many cases where the meeting place between AI and humans has revealed its shortcomings.

For example, drivers who haven’t concentrated on their semi-autonomous vehicles have experienced accidents, while a lawyer who used ChatGPT to prepare a filing was censured for the fictional citations it had added.

In manufacturing, such issues not only pose challenges to the smooth operation of production lines, they raise ethical and legal concerns. Moreover, there’s a further reputational risk should an automated process cause injury, or result in defective products.

For these reasons, manufacturers must continue to balance automation with human decision-making. Safeguarding human input within the system ensures that AI complements, rather than replaces, human expertise.

Furthermore, it ensures proper integration between localized automation, and the overall strategic operation of the business.

This is where localization steps in, Not as a peripheral concern, but as a foundational requirement for successful, scalable AI adoption worldwide.

How localization enables AI adoption at scale

As manufacturers expand AI programs across diverse global markets, one factor emerges as critical to their success. Localization is essential to tailoring AI solutions to meet the unique regulatory, cultural and operational requirements of different regions.

It’s key to the human understanding of automated systems, to the smooth integration of suppliers within a global supply chain, and to compliance with differing legal and regulatory environments.

Localized training for AI tools

Localization is of particular importance to the successful integration of AI and automated systems within a global workforce. AI adoption fails when employees don’t understand how to use computer-driven systems effectively.

This lack of understanding can push humans out of the loop, raising the risks of disruption and danger, and leaving factories at risk of over-reliance on their automated systems.

Example: Localized training in cross-regional AI deployment

A European manufacturer implementing AI-powered robotics in an Asian factory must translate training materials to ensure safe and effective operation

By translating and adapting training materials and courses for regional workforces, manufacturers can ensure their employees are qualified to operate automated systems safely and efficiently.

Similarly, by making certain that user guides and other reference material are correctly localized, workers will have a deeper understanding of automated processes, and how to maximize their uptime and efficiency.

Crucially, this allows for AI to be demystified, and thus more likely to be seen as a productivity aid than a threat to jobs and livelihoods.

Multilingual AI interfaces and voice assistants

Localization is of particular importance when it comes to the primary controls of machinery and automated systems, but also for secondary interfaces and analytics. AI-powered dashboards and voice-controlled systems are often developed in a single language – typically English – limiting their usability for non-English-speaking workforces. Worse, this creates a risk of commands or their results getting lost in translation.

It is of course critically important to ensure that instructions can be given, and alerts received, in the native language of each region. When it comes to safety-critical and urgent actions, factories simply can’t allow confusion between workers and automated systems.

But effective localization must extend fully into automation interfaces, allowing operators to receive insight and create reports in their own language. In this way, manufacturers can improve the adoption of automated systems, ensure they’re used to their full potential, and gain the best from human/machine interactions.

Example: Tailoring AI interfaces for diverse factory workforces

For the optimal, effective use by factory employees, AI-driven machinery in Germany and Mexico requires different linguistic and cultural adaptations

Just as localization improves usability, it’s equally critical for managing risk across diverse legal and regulatory environments..

Localized risk mitigation strategies

Global businesses must succeed within the multitude of regulatory backdrops found across the world. From data protection legislation such as China’s Data Security Law, through environmental rules like the USA’s Clean Air Act and Clean Water Act, down to elementary differences in worker rights and protection, each region presents unique compliance requirements.

Major manufacturers are no strangers to these differences in legal regimes, but they can be particularly challenging within the fast-emerging field of AI. Just as automation technology is undergoing rapid change, so global legislation is evolving to keep up.

Global regulators are at different points on the curve, and businesses that adopt AI must often do so in a fluid regulatory landscape.

For these reasons, it’s critical for manufacturers to localize their risk-management policies, ensuring that their AI governance is aligned with regional legal frameworks.

Not only is it imperative to understand the difference between building smart factories in, say, Sweden or Chile, it’s essential to know how attitudes and regulation continue to evolve within each territory.

Example: Adapting AI governance to regional regulatory demands

A US-based manufacturer expanding to Europe needs localized AI compliance guidelines to meet stringent EU cybersecurity regulations

Taken together, these practices illustrate how localization amplifies the benefits of AI — and helps manufacturers navigate its complexities with confidence.

Operational gains, strategic risks: Getting AI right

For manufacturers, automation has long been a way to improve productivity and efficiency. The rise of ever smarter, AI-powered systems is driving this to transformational levels. But alongside the undoubted opportunities and benefits, adopting AI at scale presents many challenges – and especially so for businesses competing in multiple territories.

Localization is a key enabler for firms seeking to navigate these challenges. It supports the upskilling of existing workforces, and underpins the ability of workers and machines to get the best from each other. It helps businesses understand the cultural and behavioural attitudes to AI in each territory, and deploy automation in suitably tailored ways.

Moreover, localization is key to understanding and operating within the complex, differing, and evolving regulatory environments encountered across the world. Compliance depends on a localized understanding, built on the fundamentals of both local and localized knowledge, kept constantly up to date.

AI is transforming manufacturing, offering incredible benefits, but increased risks. To reap the rewards, manufacturers must find the balance between technological innovation and human skill. To compete in a global industry, localization emerges as a prerequisite for success.